Home – Project Detail

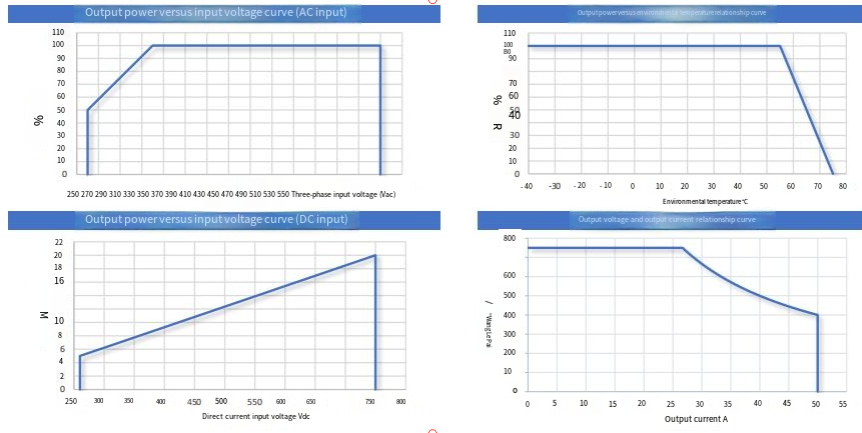

The BIDC-F75025 AC/DC hybrid conversion module supports both AC and DC inputs, integrating the charging of battery packs by the power grid and the charging of electric vehicles by battery packs into one. This module features high efficiency, high power factor, high power density, minimal electromagnetic radiation and interference, and high reliability. It is a charging module at the international leading level. The BIDC-F75025 hybrid conversion module can also be used as a pre-conversion for wind and solar energy, playing a unique role in distributed generation and smart microgrid applications.

Unique Features

Main Features:

Application Scenarios:

Technical Parameters

Working Environment Conditions

AC Input

DC Input

DC Output

Monitoring

Alarms and Protections

Product Reliability and Safety Regulations

Dimensions and Weight

Ordering Information

*The product is constantly being innovated. If there are any changes in specifications, no prior notice will be given.

SunCare Hospital, a leading healthcare institution committed to sustainable operations and patient well-being, partnered with us to transition its energy source to solar. The project involved the full design and installation of a customized solar power system to reduce operating costs, increase energy reliability, and support the hospital's green initiatives.

This project was designed to meet the hospital’s energy needs while promoting sustainability, reducing costs, and ensuring uninterrupted service for patients and essential medical operations.

We provided a complete solar solution tailored to the hospital’s needs, ensuring performance, safety, and long-term energy savings without disrupting daily operations.

We analyzed usage patterns and infrastructure to design a system that meets specific energy needs.

Our team installed efficiently with zero interruption to hospital operations and strict safety procedures.

We created a solar layout that maximizes efficiency while matching the hospital’s structure and goals.

We integrated smart monitoring and backup support to ensure continuous power for critical medical equipment.

This project is more than just an energy upgrade, it is a commitment to health, sustainability, and community leadership. The SunCare Hospital solar installation reflects how renewable energy can enhance essential services without compromise.

Solarize brings cutting-edge clean energy solutions to life, empowering homes, businesses, and public spaces with sustainable power that transforms everyday living.