Home – Project Detail

The BIM series 3000-3600-4200W is a multi-functional bidirectional PCS module, which adopts a high-efficiency soft-switching patented topology and digital control technology. It integrates a pure sine wave inverter, high-power charger, UPS bypass, RS485 and CAN communication ports, parallel operation and other functions.

| Module Function | Model | BIM48-3000 | BIM48-3600 | BIM48-4200 |

|---|---|---|---|---|

| Output Function | ||||

| Inverter Power | 3000W | 3600W | 4200W | |

| Charging Power | 3000W | 3600W | 4200W | |

| Inverter Output Voltage | 100Vac, 110Vac, 120Vac, 220Vac, 230Vac, 240Vac (optional) | 220Vac, 230Vac, 240Vac (optional) | ||

| Inverter Output Frequency | 50Hz, 60Hz (optional) | |||

| Inverter | Overload Capacity | 100%<P<=110% peak power, duration 20s 110%<P<=125% peak power, duration 5s 125%<P<=150% peak power, duration 2s 150%<P<=200% peak power, duration 200ms |

100%<P<=150% peak power, duration 2s 150%<P<=200% peak power, duration 200ms 200% peak power |

|

| Output Waveform | Pure sine wave | |||

| ThdU | 3%@resistive load | |||

| Efficiency | Max.91.2%@120Vac, Max.93.5%@220Vac | Max.93.5%@220Vac | ||

| Start-up | Supports 6 units of wired parallel operation | |||

| Rectification (Charging) | AC Input Voltage | 90-264Vac | 176-264Vac | |

| AC Frequency Range | 47-63Hz | |||

| Maximum AC Input Current | 30A (放宽至30A,but system design needs to consider regulations, e.g., maximum AC input 15A in the US, domestic maximum AC input current set to 16A) | |||

| PF | 0.99@100%Load | |||

| ThdI | <5%@100%Load | |||

| Maximum Charging Current | 60A | 72A | 80A | |

| Charging Voltage Range | 40-59.5Vdc | |||

| Voltage Ripple | Max.700mV (0-20MHz) | |||

| Efficiency | Max.92.5%@120Vac, Max.94.5%@220Vac | Max.94.5%@220Vac | ||

| Charging Management | Managed by host computer | |||

| Ac Bypass Switching | Ac Bypass Current | Max.15A | ||

| Switching Time | Typical 20ms | |||

| Environmental Conditions | Operating Temperature | -25°C ~ +70°C, derating above 45°C | ||

| Storage Temperature | -40°C ~ +70°C | |||

| Relative Humidity | ≤95%RH, no condensation | |||

| Cooling Method | Forced air cooling | |||

| Altitude | 2000m, for altitudes above 2000m, derate by 1°C for every 200m increase in altitude. | |||

| Atmospheric Pressure | 79kPa ~ 106kPa | |||

| Response Time | Max.10S (from host computer sending instruction to output) | |||

| Leakage Current | Max.10mA | |||

| Insulation Resistance | Insulation resistance between DC part, AC part and outer casing, and between AC part and DC part ≥10MΩ | |||

| Noise | Max.58dB (1m) | |||

| Others | Insulation Strength | AC terminal to casing: 1500Vac/50Hz or 2120Vdc60S, no breakdown, no flashover, steady-state leakage current <10mA; AC terminal to DC terminal: 3000Vac/50Hz or 4240Vdc60S, no breakdown, no flashover, steady-state leakage current <10mA; DC terminal to casing: 500Vac/50Hz or 710Vdc60S, no breakdown, no flashover, steady-state leakage current <10mA; AC terminal to CAN or 485 terminal: 3000Vac/50Hz or 4240Vdc60S, no breakdown, no flashover, steady-state leakage current <10mA; DC terminal to CAN or 485 terminal: 500Vac/50Hz or 710Vdc60S, no breakdown, no flashover, steady-state leakage current <10mA; Casing to CAN or 485 terminal: 500Vac/50Hz or 710Vdc60S, no breakdown, no flashover, steady-state leakage current <10mA; |

||

| Grounding Resistance | Grounding resistance ≤0.1Ω, withstand current ≥50A | |||

| Safety Regulations | TBD | |||

| EMC | EN55032, EN55035, IEC61000-3-2, IEC61000-3-3, FCC | |||

| MTBF | 250KHrs, 25°C, 80% load | |||

| Weight | Max.4Kg |

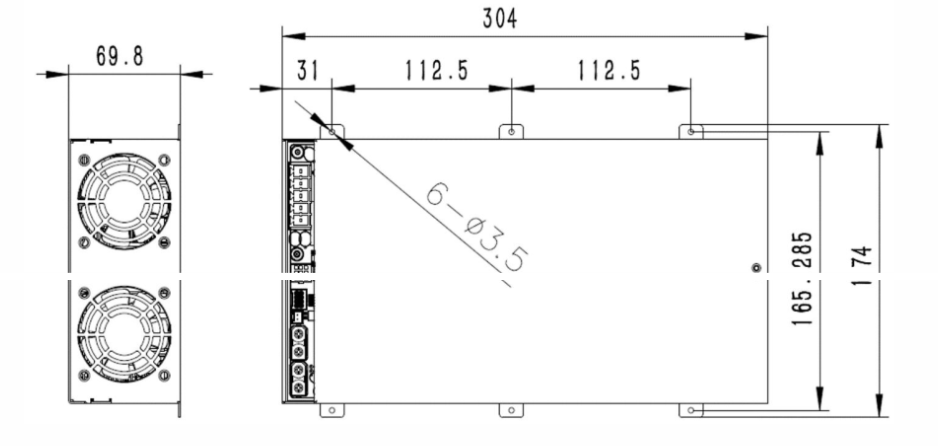

Installation Instructions: Module installation and fixation There are 3 installation holes on each side of the entire module. They are fixed by 3 M3 screws. The specific installation dimensions are shown in the following figure:

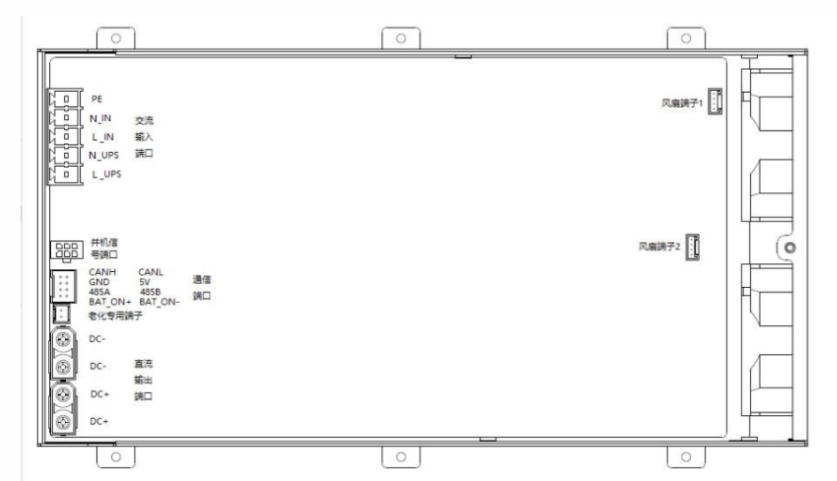

Module input/output terminal description:

Module input/output terminal description:

SunCare Hospital, a leading healthcare institution committed to sustainable operations and patient well-being, partnered with us to transition its energy source to solar. The project involved the full design and installation of a customized solar power system to reduce operating costs, increase energy reliability, and support the hospital's green initiatives.

This project was designed to meet the hospital’s energy needs while promoting sustainability, reducing costs, and ensuring uninterrupted service for patients and essential medical operations.

We provided a complete solar solution tailored to the hospital’s needs, ensuring performance, safety, and long-term energy savings without disrupting daily operations.

We analyzed usage patterns and infrastructure to design a system that meets specific energy needs.

Our team installed efficiently with zero interruption to hospital operations and strict safety procedures.

We created a solar layout that maximizes efficiency while matching the hospital’s structure and goals.

We integrated smart monitoring and backup support to ensure continuous power for critical medical equipment.

This project is more than just an energy upgrade, it is a commitment to health, sustainability, and community leadership. The SunCare Hospital solar installation reflects how renewable energy can enhance essential services without compromise.

Solarize brings cutting-edge clean energy solutions to life, empowering homes, businesses, and public spaces with sustainable power that transforms everyday living.